Quality

Our Quality Promise

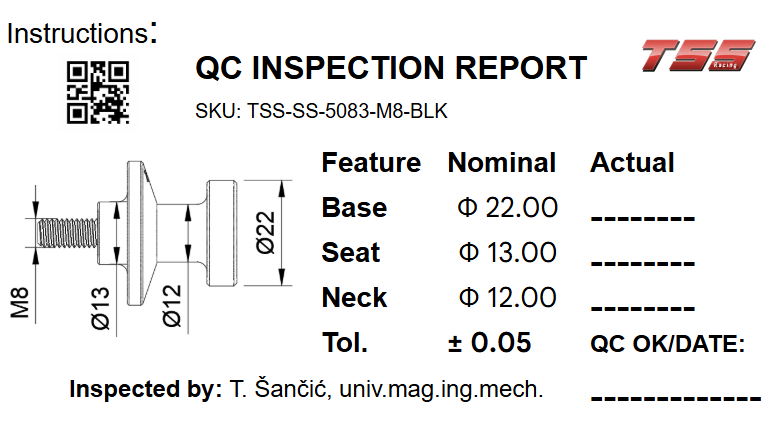

Every TSS component is delivered with a unique LOT identification and a hand-signed QC Inspection Report, providing physical proof of its precision and material origin.

The TSS Birth Certificate

This is what you receive with every part. Our Individual QC Inspection Report isn’t just a flyer; it’s a verified record of your component’s actual dimensions, measured in our 20°C lab. When we say ±0.05 mm precision, we don’t just promise it—we document it and sign for it.

Total Traceability

Every component is assigned a unique LOT number, providing 100% traceability from the raw German EN AW 5083 aluminum block to the final hand-signed report. You can see the material grade, the specific batch number, and the MIL-A-8625F anodizing standard—all verified before your part leaves our facility.

At TSS Racing, quality is an engineering certainty. Our process is strictly overseen by a lead Mechanical Engineer (univ.mag.ing.mech.) to ensure every component meets aerospace-grade requirements. Every part is verified in our temperature-controlled laboratory at 20°C using calibrated Mitutoyo & Mahr instruments to guarantee a strict ±0.05mm precision.

We don’t believe in batch sampling; our protocol requires 100% inspection on every single component. This rigorous process is documented in a hand-signed QC Inspection Report that accompanies your product, providing full traceability from the raw material to the final precision-machined component.

Quality Control Process

From raw material to finished part, quality is built into every step.

Material Verification

All aluminum stock is verified against material certificates. We only use German-sourced AL 7075-T6 and AL 5083 marine grade.

Pre-Production FEM

Finite Element Method analysis validates structural integrity before any machining begins. Critical stress points are identified and designs optimized.

In-Process Monitoring

HAAS CNC machines provide real-time monitoring. Tool wear and dimensional accuracy are tracked throughout production.

Dimensional Inspection

Every critical dimension is measured with calibrated micrometers and calipers. Tolerance: ±0.05mm on all specifications.

Surface Quality Check

Visual inspection ensures surface finish meets standards. Machining marks, anodizing quality, and engraving depth are verified.

Documentation & Packaging

QC reports and material certificates are generated. Parts are carefully packaged to prevent damage during shipping.

Our Process

CAD Construction

Every part begins with precise 3D modeling in professional CAD software.

FEM Analysis

Finite Element Method simulation validates strength and identifies stress points before any material is cut.

Iterative Refinement

Mass and strength are optimized through multiple design iterations until the perfect balance is achieved.

CAD/CAM Programming

Optimal machining processes are developed through CAD/CAM software for each unique component.

CNC Manufacturing

Parts are machined individually on HAAS CNC equipment — no stamping, each piece made to order.

Quality Control

Every part is measured and verified. QC documentation and material certificates ship with each order.

Certified Materials

We use only aerospace and marine-grade materials with full documentation.

AL 7075-T6

Aircraft-grade aluminum alloy with exceptional strength-to-weight ratio. Ultimate tensile strength: 572 MPa. Used for high-stress structural components.

AL 5083 Marine Grade

Superior corrosion resistance and excellent weldability. Used for components exposed to harsh environmental conditions.

German Sourcing

All aluminum sourced from certified German suppliers. Full traceability from mill to finished part with documentation.

Certificate Included

Every order ships with material certificates showing chemical composition, mechanical properties, and batch traceability.

Manufacturing Equipment

HAAS CNC Machines

American precision manufacturing equipment known for reliability and accuracy. Spindle speeds up to 8,100 RPM for optimal surface finish.

CAD/CAM Integration

Direct CAD-to-machine workflow eliminates manual programming errors. Tool paths are optimized for each unique geometry.

Calibrated Instruments

Mitutoyo micrometers and calipers calibrated annually. All measuring equipment traceable to international standards.

Climate-Controlled Shop

Temperature-controlled environment ensures dimensional stability. Thermal expansion is accounted for in all measurements.

Why Quality Matters

Performance

Precise tolerances mean parts fit perfectly the first time. No filing, no forcing, no frustration. Components work together as engineered.

Durability

FEM-validated designs eliminate stress concentrations. Certified materials ensure consistent mechanical properties. Parts last season after season.

Safety

Racing puts extreme demands on components. Our engineering standards ensure parts perform reliably when it matters most — at full throttle.

Engineering You Can Trust

Experience the TSS Racing difference. Every part backed by documentation, certified materials, and precision manufacturing.